Story

Story Vol.19

RELIEF: Crafted in Collaboration with Ceramic Japan and Lemnos

Ceramic Japan and Lemnos create beautiful products that enhance everyday life through their dedication to design-driven craftsmanship. Designer Ryosuke Fukusada reflects on his collaboration with these two companies, through which he achieved an exceptional level of design quality.

[ Text: Ryosuke Fukusada ]

Inspired by an Original Idea from 2014

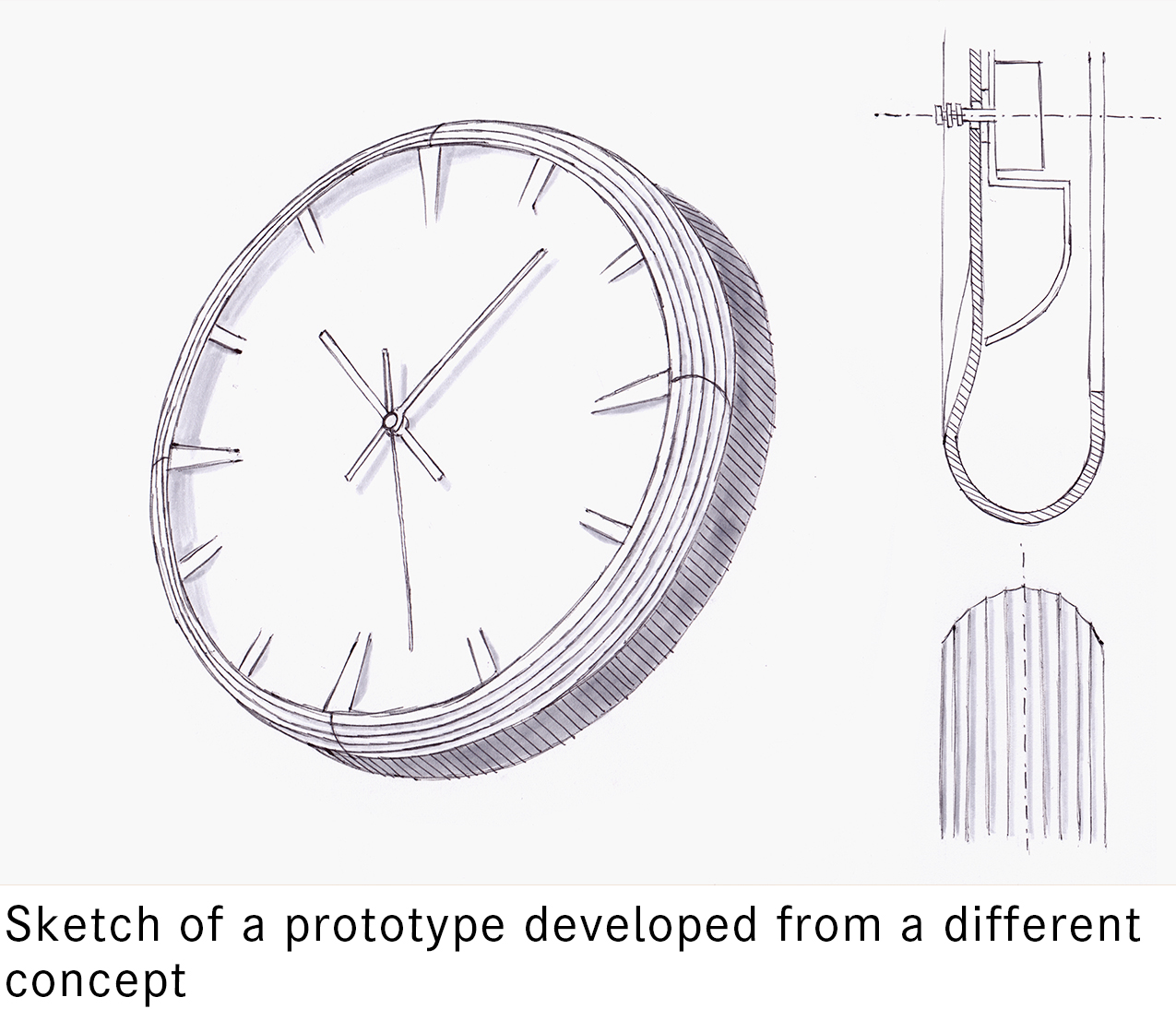

The original idea for RELIEF dates back to 2014, when I first received a design request from Lemnos. Among the proposals I presented was a clock design that incorporated porcelain. I envisioned a piece with a porcelain frame paired with a glass panel, but bringing it to life proved to be difficult. Looking back at those early design sketches, it’s clear that the concept lacked practicality; I had yet to fully understand the complexities of porcelain production.

The original clock design proposals were never realized, but several years later, a new development project began with Ceramic Japan in Seto, a collaboration made possible through my connection with Lemnos. By observing the porcelain production process firsthand and gaining a deeper understanding of its methods, I created a candle holder using a technique known as “slip casting.” Through the trial and error of bringing this product to market, my understanding of porcelain grew considerably.

By early 2019, when I began developing a new clock in partnership with Lemnos, the original idea had long since faded from my memory. During the planning discussions, the porcelain clock I had proposed before resurfaced, and its concept became the project’s central focus. Although the idea had not been realized previously, my collaboration with Ceramic Japan increased my understanding of porcelain and allowed me to shape the prototype for a new design concept.

Beautifully Emerging Markers, Refined Through Repeated Prototyping

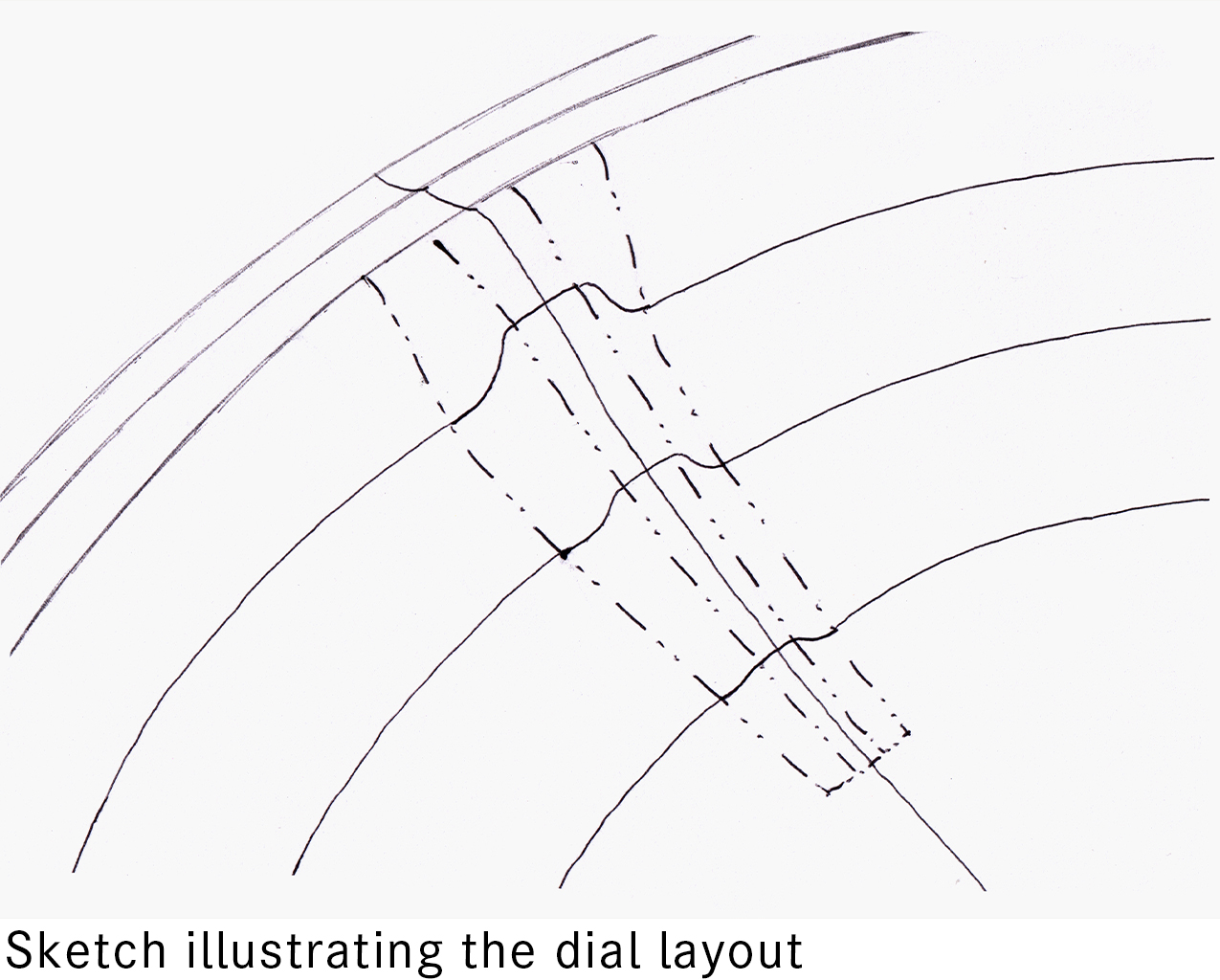

One of the clock’s defining features is its gently concave, mortar-shaped dial, which highlights the porcelain’s subtle character, complemented by smoothly raised markers that emerge gracefully, like a relief to the eyes. The markers’ forms were meticulously refined through numerous adjustments and carefully balanced to stand out clearly and elegantly without compromising functionality.

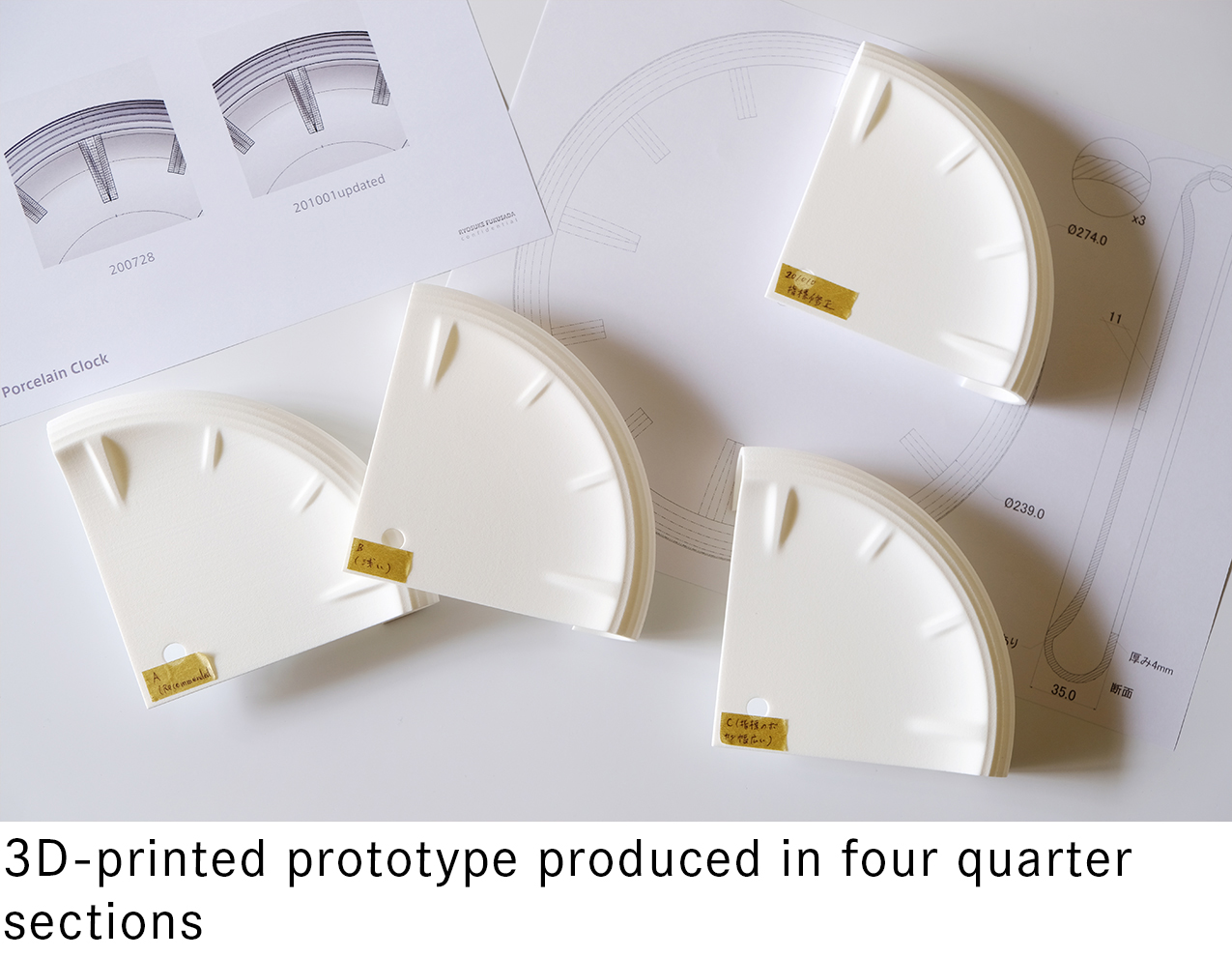

The four markers at the top, bottom, left, and right are wedge-shaped and gradually narrowed from the outer edge toward the center. When designed with straight lines, the middle sections appeared visually thin, so we intentionally introduced a subtle curvature to give the markers a fuller, more balanced appearance. To refine the balance, we repeatedly modeled the shape in 3D CAD, output prototypes through 3D printing, and evaluated them in physical form until the final design was determined.

Ceramic Japan’s Expertise in Ceramics

After finalizing the main form, we created a mold and produced the piece using a slip casting process. The final clock diameter was set at 274 mm for a comfortable scale, but the ceramic prototype had to be made larger to account for shrinkage during firing. Producing a piece of this size through slip casting proved to be a significant challenge.

The thickness of the porcelain varies from the moment the slip is poured into the mold until it is removed. Even a slight misstep when taking the mold off can cause the piece to warp. Ensuring a uniform, flawless finish demands the expertise of skilled artisans.

The timing for draining the slip is carefully adjusted according to daily variations in temperature and humidity. When removing the plaster mold, the back is taken off first and left for a period before the front is removed, thus giving the piece time to stabilize. These processes draw directly on the expertise developed through years of hands-on experience.

Once the body has dried, any burrs from the mold are carefully trimmed with a knife, and minor surface irregularities from the slip flow are smoothed out using a sponge. After this meticulous work, the piece is ready for firing in the kiln.

Firing the piece at over 1250°C produces the beautiful white porcelain body. However, its large size makes it prone to imperfections (e.g., tiny black spots caused by iron particles), so achieving the perfect finish is no easy task.

By leveraging the extensive experience and technical skill of Ceramic Japan, these challenges were expertly addressed, allowing the body to be successfully produced.

Commitment to Color Variations

After the main design was finalized, we devoted significant time to developing color variations and refining production methods, with the goal of reducing material loss during manufacturing. If we were to merely apply glaze for color, the thickness of the coating would change the perceived shape, preventing the delicate nuances of the design from being fully realized.

Despite developing the product during the COVID-19 pandemic, we sometimes met face-to-face to collaborate and discover the best ways to maintain the form. Alongside the white porcelain, we successfully produced two additional color variations.

The three variations—porcelain white that highlights the material’s natural beauty, matte blue, and beige—each display elegant shading, elevating the atmosphere of any interior.

Ceramic Japan and Lemnos are united by a shared philosophy: a design-centric approach, a sincere dedication to craftsmanship, and a commitment to creating beautiful products that enrich everyday life. Their collaboration combined clockmaking expertise with a deep understanding of porcelain, which allowed us to realize a clock design of exceptional quality.

Ryosuke Fukusada

Born in 1979 in Osaka, Japan. He studied product design at the Kanazawa College of Art from 1998 to 2002. He then worked for Sharp Corporation in Japan as a designer for consumer electronic products until 2007. After transferring to Italy, he graduated from the Domus Academy, Master in Interior and Living Design course. From 2008 to 2012, he worked for the Studio Urquiola in Milan as an assistant designer of product design for Patricia Urquiola. He then started his own design studio from October 2012 in Kyoto, Japan. He currently works with some international clients.

https://ryosukefukusada.com/en/