Story

Story Vol.20

STORY OF PANECO CLOCK

The global issue of clothing waste is becoming increasingly serious, with 1,300 tons of garments discarded every day in Japan alone. To address this problem, a circular fiber-recycling material called 「PANECO®」 was developed. In this article, Hisae Igarashi shares her vision for the PANECO CLOCK, a design that combines beauty with meaning to convey a thoughtful message.

This clock was developed to highlight the material’s full potential, while raising awareness of environmental issues.

[ Text: Hisae Igarashi ]

Discovering PANECO

One day, I met someone taking independent action against the issue of “fashion loss.”

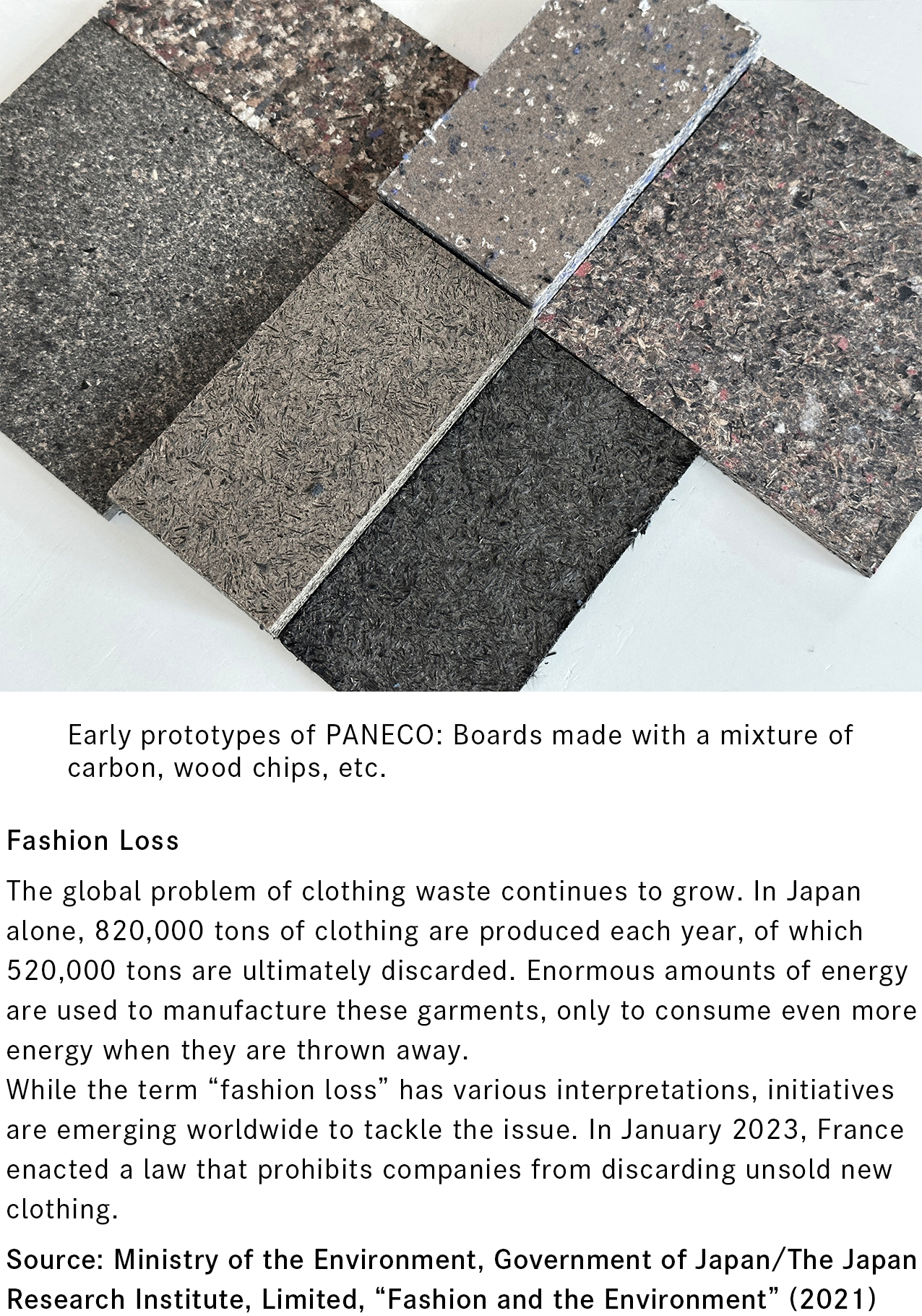

That person was Kazuhiro Hara of WORKSTUDIO Corporation, a company that designs, manufactures, and sells store and office fixtures. He unexpectedly visited my office in April 2020, just as the COVID-19 pandemic was beginning. As a fashion enthusiast, Mr. Hara wanted to create interior panels from discarded clothing. Since such panels are widely used in apparel shops, fixtures, and interiors, he felt a strong responsibility to act. He shared his vision with great enthusiasm and showed us some experimental samples. The idea of transforming discarded garments into panels made perfect sense to me. I immediately felt empathy and believed in the project’s potential. At the same time, I could see the challenges involved in making it a reality. The samples revealed his trial-and-error process, in which he mixed textile fibers with materials like paper, wood, and carbon to achieve the strength of conventional panels. Their surface and texture made it clear that a finishing layer would be necessary. Although the project was still in its early stages, I felt genuinely inspired to help tackle the problem of fashion waste through interior design.

After several rounds of discussion, I suggested exploring the possibility of a truly circular recycling system, which could be reused repeatedly, rather than ending after a single cycle. To this end, I proposed rethinking the raw materials from the ground up. For a while, our communication stopped, and I assumed the idea had been put aside. To my surprise, Mr. Hara later returned with a sample panel made from over 90% discarded clothing. I was deeply impressed and felt compelled to collaborate. Named “PANECO,” the panel marked a significant step toward realizing a circular economy. Its surface still revealed subtle traces of its fibrous origin, which suggested the potential to be used—even without additional finishing.

The PANECO Recycling System

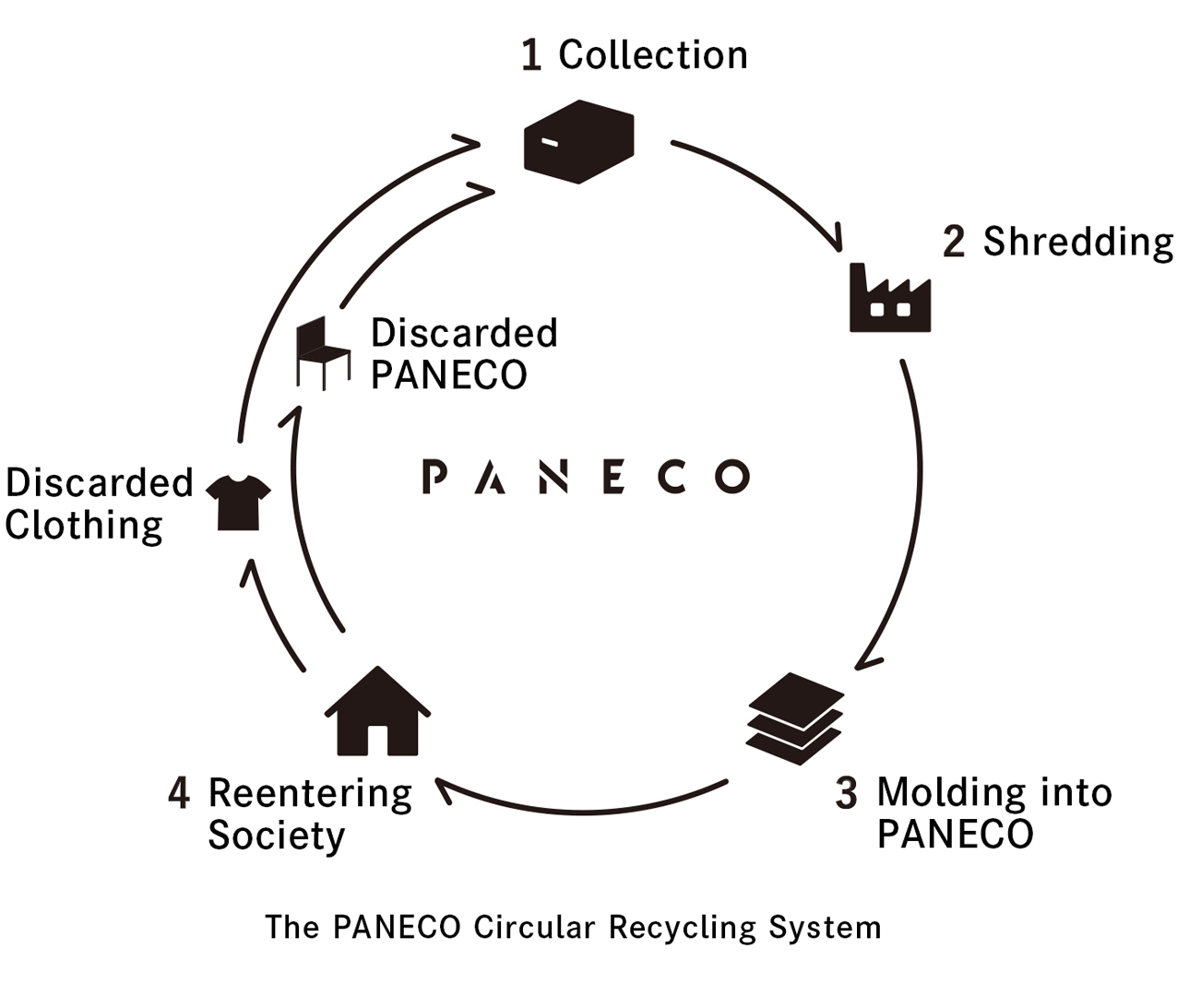

1) Clothing is collected from society, and zippers, buttons, etc. are removed at welfare facilities.

2) The garments—now free of metal parts—are shredded into fine fibers.

3) The fibers are molded into PANECO panels.

4) These panels are used in fixtures and interior spaces, thus re-entering society.

When PANECO panels reach the end of their use, they can be collected, shredded, and remade into new panels. This is a key feature, as few materials have a fully established system for re-recycling. Upcycled materials are integrated into a circular recycling process. The PANECO recycling system embodies this approach to reduce environmental impact.

PANECO’s Appearance

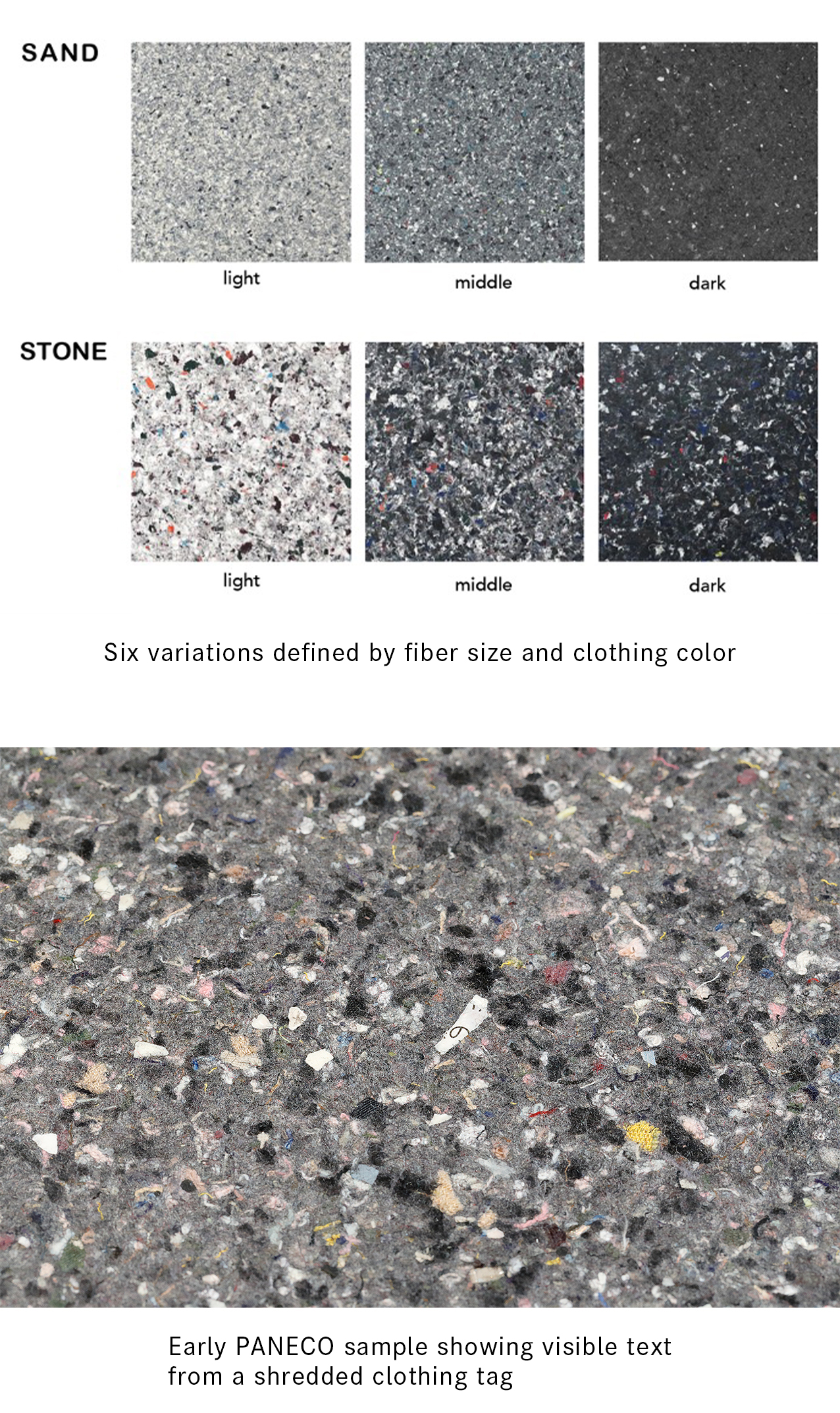

PANECO’s appearance changes depending on the types of clothing used at the time. Most often, the mixed fibers result in a gray tone, much like how different paints blend together. The size of the shredded fibers can reveal subtle hints of their textile origins. Upon closer inspection, you might notice flecks of glitter, or traces of the original garments, while panels with a predominance of blue fibers may include denim. In rare cases, PANECO sometimes contains shredded paper tags from clothing, with fragments of printed text still visible. In this way, PANECO is like a fossil, which captures the spirit of its time and reveals a variety of unique expressions. Currently, PANECO is offered in two fiber textures: “Sand” and “Stone,” categorized by the size of the shredded fibers, and in three color tones: “Light,” “Middle,” and “Dark.” Since PANECO is made from a diverse mixture of discarded garments—rather than fixed raw materials—each panel naturally varies in color depth. This individuality is an essential part of what makes PANECO unique.

PANECO at the Exhibition

The first PANECO exhibition took place in May 2021 at Moririn Co., Ltd.’s showroom in Higashi-Nihonbashi, showcasing furniture made from PANECO panels composed of recycled clothing and designed for long-term use.

The shelving and storage units were designed adaptably and durably in modular sections, so they could be rearranged to fit new spaces, even after moving. When they eventually reach the end of their life, the panels can be recycled back into PANECO. This circular system promotes long-term use and helps reduce environmental impact. For furniture production, WORKSTUDIO employed large Thomson cutting dies. Typically used for small items (e.g., puzzles), adapting them to cut large furniture components was a major challenge. Despite initial concerns, the team’s persistence paid off and successfully brought the designs to life.

Clock Development

In the summer of 2021, when I was commissioned to develop a wall clock, I decided to experiment with PANECO. The project aimed to create a product made from clothing with environmental considerations in mind. After receiving approval from the manufacturer, Takata Lemnos, the design process began. Through trial and error, we explored PANECO’s potential as a material, using techniques such as laminating, carving, and printing.

Thomson Die Cutting

Thomson die cutting is a process that punches a sheet of thick paper using a metal blade. The technique is named after John S. Thomson, who founded the Thomson Machinery Company in the United States and introduced the first Thomson die-cutting machine in 1909. The cutting process performed with this machine is called “Thomson die cutting,” and the molds used are known as “Thomson dies.”

Thomson die cutting can be applied to a wide range of materials (e.g., paper, metal, resin, and rubber). It is commonly used for product packaging (e.g., paper boxes), in which the outer shape and perforations can be cut in a single operation. Jigsaw puzzles are also produced using Thomson dies. However, PANECO presented a new challenge. With a thickness of 5.5 mm and a wood-like hardness, it required a careful approach to cut successfully. We decided to take on the task. Although we had previously managed to produce fixtures for an exhibition, achieving the level of quality required for a wall clock was a completely new test.

PANECO at the Sustainable Fashion Expo

In the fall of 2021, PANECO was showcased at the Sustainable Fashion Expo held at Tokyo Big Sight. The booth concept, “Spaces Created with PANECO,” featured Wall Box Units made from box-shaped PANECO panels that could be easily assembled and reconfigured to form adaptable environments. This served as a proposal for reusable, temporary spaces. The Wall Box Units created four distinct zones (e.g., retail and private spaces), all furnished with fixtures and furniture crafted from PANECO. The exhibit provided an excellent opportunity for sustainability-conscious visitors to experience and learn about PANECO firsthand.

At the venue, we also presented a prototype of the PANECO CLOCK, made using a Thomson die. Measuring one meter in diameter and designed for public spaces, the large clock allowed light to filter through its die-cut openings, which created a striking visual effect.

PANECO CLOCK

With the prototypes of the PANECO CLOCK, we faced difficulties, as the Thomson die-cutting process did not produce clean results. As PANECO continued to evolve, a thinner 3 mm version was developed. By using this improved material, the Thomson die-cutting process succeeded, which made it possible to use PANECO as the material for the clock’s dial.

After extensive design studies, two final models were determined: the Number type, which features numerals, and the simple Slit type. The Number type uses the fine-textured “Sand” finish to ensure that the numerals appear clear, and it is available in two colors: “Dark” and “Light.” The Slit type employs the coarse-textured “Stone” finish paired with a “Middle” tone to highlight PANECO’s fiber-based character and rich particle accumulation. Additionally, the Slit type will be available in small-lot, irregular PANECO panels, with colorful variations that naturally emerge during production.

The PANECO CLOCK is the perfect size for appreciating the material’s rich character. With this clock, we may continue to uncover and highlight even more of PANECO’s unique appeal. In the world of craftsmanship, growth comes from countless failures and becomes the energy that drives us to pursue the next challenge.

2022 Milan Design Week

In June 2022, in the aftermath of the COVID-19 pandemic, PANECO was showcased at Milan Design Week. The new 3 mm version proved to be flexible enough to allow bending, which made it possible to present spatial designs featuring curved surfaces.

With “PANECO HOUSE” as its theme, the exhibition showcased home-use furniture crafted from PANECO (e.g., tables, chairs, shelves, bookcases, and sofas). Prototypes of the PANECO CLOCK were also unveiled and received enthusiastic acclaim from visitors.

In December 2022, the PANECO CLOCK was finally launched as the first official PANECO product.

We are entering an era focused on reducing waste and keeping resources in circulation. By marking the passage of time, the PANECO CLOCK serves as a messenger of the challenges we face and could become a catalyst for new values and ways of thinking.

Hisae Igarashi

Interior designer

Born in Tokyo. Graduated from KUWASAWA Institute of Design. 1986–1991, joined the KURAMATA Design Office. 1993, established IGARASHI DESIGN STUDIO. Initially centered around the design of commercial and other spaces, installation, and furniture, moving to the development of products, kitchenware, infant facility play equipment, etc., the scope is now expanding to “food, clothing, housing and education”. Member of the jury for the Good Design Award, and professor at the Department of Scenography, Display and Fashion Design, Musashino Art University. Winner of the Good Design Award, the Kids Design Award and other many awards.

http://www.igarashidesign.jp/